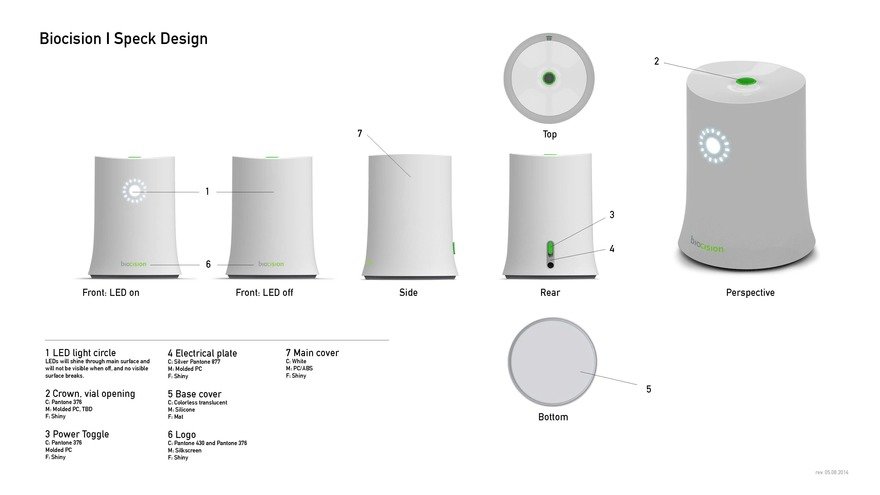

The Client BioCision, LLC develops sample standardization tools for sample handling and storage procedures. The Company offers cell freezing containers, cooling workstations, freezing box, cooling rack, cooling plate modules, and warming platforms. BioCision operates in Larkspur, California and markets to the pharmaceutical, biotechnology, academic, and health care industries worldwide. “New ideas, new technologies, and new ways of thinking are driving our future.” -Brooks Life Sciences/BioCision The Product The ThawSTAR Thawing System replaces unstandardized manual methods of thawing samples with controlled profile thawing and can be leveraged early in the R&D phase and scaled into commercial manufacturing and point of care. The Challenge Speck Design was charged with creating an automated cell thawing device that added repeatability and consistency to the warming process used to revive the cryo-preserved cells. The product needed to eliminate thawing errors due to human mistakes (e.g. subjective determinations, distractions, etc). Several factors including cell size and choice of cryopreservation media needed to be considered since these can affect the optimal thawing profile, viability, and function. The Process *Don’t have any info on this The Outcome Before the device, the thawing was performed by lab technicians using the hot water bath technique. The ThawStar has drastically improved this process forever and is becoming an integral part of the existing and future BioCision freezing and thawing product families. The “look and feel” of the product reflected the fun, colorful, and playful experience of the cool tools product lines. The cell thawing device was the next addition to a set of tools that promote better yields and outcomes through improved standardization.

e