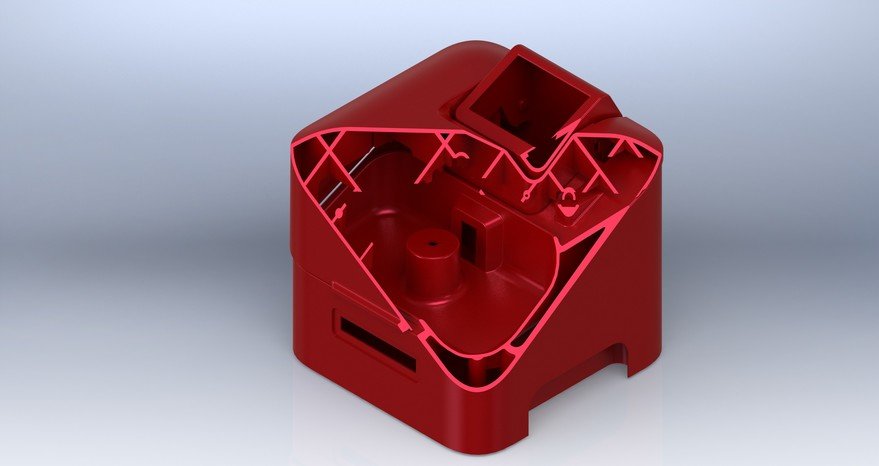

SGW Designworks was approached by the client with a problem. Another firm had designed a beautiful, but impossible aluminum enclosure for a specialty electronic device. The client needed to quickly get fifty units produced for field testing by a federal agency, but did not have a manufacture-able design to use. SGW was able to maintain the existing design language in a complete redesign of the enclosure. Injection-molded plastic was an ideal choice of material for long term production. A modified version of the design optimized for production using soft tooling was also provided to facilitate the initial test run. The change in material necessitated a completely new hinge and lock system for the unit. SGW Designworks was able to quickly develop, iterate, and finalize the hinge design using digital simulation, and validation with 3D printed prototypes prior to finalizing the design.

e