Adventures in Laser Kerf Bending

If you're going to go curved, you may as well go pretty

When Shaun Crampton designed a bentwood housing for his self-built radio receiver, he didn't go with steam-bending. Instead the software developer went the lasercutter route, cutting accordion lines to turn the walnut-veneered plywood into its own hinge. The result is not only pleasing to the eye, but looks like something Braun would have designed in the 1930s, had they had access to a lasercutter back then:

Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional)Using a lasercutter to create kerf bending patterns or lattice hinges has been popular since affordable laser cutters first hit the market, and in the years since, folks have experimented with plenty of different patterns. A lattice hinge is a great way to provide both form and visual interest, and while the results wear their CNC on their sleeve, so to speak, it's a look that many are happy to live with.

Martin Breuer took an engineer's approach to his tests, producing five variants of his own transmitter box:

Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional)On his website he not only rates each design in four categories—Pliability, Tensile Strength, Torsional Strength and Normal Strength—but provides the CAD file for those that want to repeat his experiments.

Patrick Fenner's used a lasercutter to make these sketchbook covers, and has also run a series of kerf-bending tests to determine ideal radii for materials of a given thickness (including plastic).

Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional)You can check those out, along with the files, on Fenner's page.

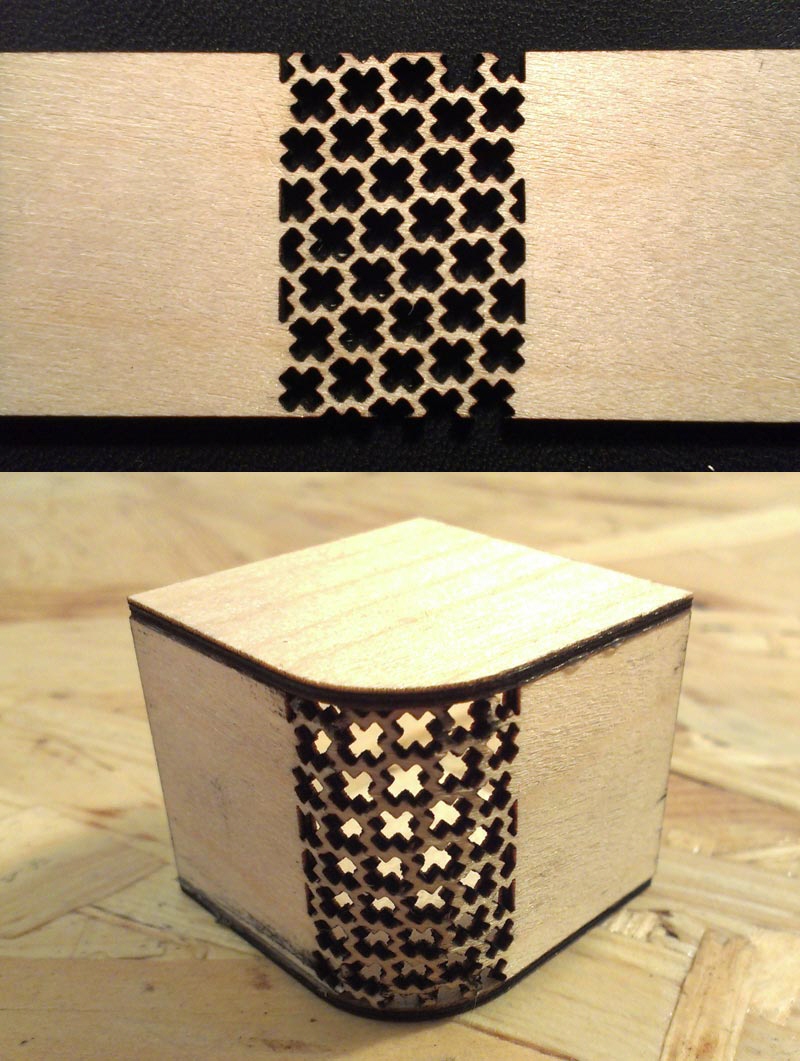

When it comes to sheer creativity of patterns, Aaron Porterfield seems the cake-taker with these experiments:

Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional) Enter a caption (optional)

Enter a caption (optional)Porterfield has an Instructable discussing the merits of each type here. (And like the others, he's included the files.)

-

o11Favorite This

-

Q2Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

Great way to create bending shape out wood! We at WE LASERS often laser cut designs similar to this. Nice application.