The Strange Ways That They Used to Transport Cars by Train

Vertically, for instance

Here's a next-to-last-mile problem. Back in the day, after all of the considerable design, engineering, manufacturing, sales and marketing work that goes into producing a new car was completed, automakers faced a logistical problem: How to get the product from their centralized factories to the consumers scattered across the country. In the early days of the automobile, when buyers were few, it was a viable option to stick two autos in a train boxcar and ship them off.

But as demand began to grow, the shipping capacity had to match. Sometime in the 1940 America's auto manufacturers, in collaboration with the railroads, developed a special car-carrying boxcar that would utilize the overhead space. At 50 feet in length, it had ten extra feet on the standard 40-foot boxcars of the time.

Loading the thing was a pain in the neck, as a car was manually pushed inside, then jacked up towards the ceiling at an angle to accommodate a car coming in underneath it. (While I initially assumed the illustration above was incorrect in depicting the cars' orientation within the boxcar, it is in fact accurate as the automobiles had to be loaded in via a sliding door in the middle of the boxcar.)

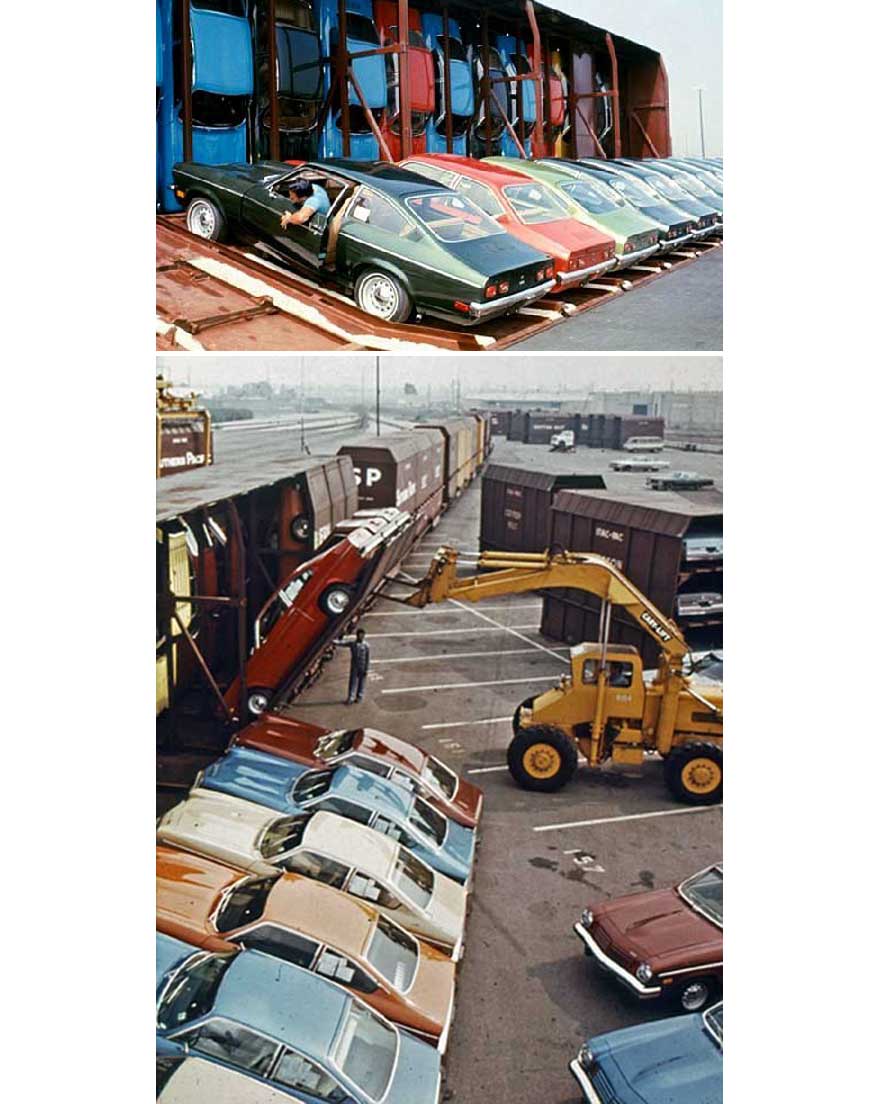

By the '50s and '60s, two- and three-level "autoracks," primarily open-air auto-carrying traincars similar to what you'd see today, were developed. They were logical, economical and frankly, kind of boring.

Of far more interest is the strange experiment GM embarked on starting in the late '60s. As they prepared to launch their Vega—a truly awful, hideous, forgettable stain on Chevrolet's past meant to mark their entry into the compact car market—they developed a novel way to ship them: Vertically.

Vegas were short enough in length that they could clear the roofline of train car when placed straight up-and-down. So a special train car was designed where the sides flipped down to form ramps. The car was driven onto the ramp, secured, and then a special forklift folded each ramp closed, with the cars hanging off of them inside.

In this manner, dubbed the "Vert-a-Pac" system, they could cram thirty Vegas inside a then-standard 89-foot-long train car. This went a long way towards keeping the Vega's shipping costs down and subsequent sticker price lower.

As most of you know, cars aren't meant to be vertical, not with all of those fluids inside. And interestingly enough, the Vega was specifically designed to deal with this unusual form of transportation. As the Car Lust Blog explains,

In order to be able to travel nose-down without leaking vital fluids all over the railroad—one of the design specifications was that the car had to be loaded straight off the assembly line, and drivable the moment it was unloaded—Vegas destined for transport by rail were equipped with the "VK5" option package. This consisted of a baffle in the oil pan to keep the #1 cylinder from being flooded with oil, a special wiper fluid bottle mounted at a 45-degree angle, a battery with off-center filler caps, and an extra hose in the fuel system. There was also a plug in the fuel tank vent and some plastic spacers reinforcing the motor mounts which were supposed to be removed by the dealer before delivery.

Like the Vega, this method of shipping—and of designing a car to deal with vertical storage without creating a fluids-based disaster—eventually fell by the wayside.

-

oFavorite This

-

Q9Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

That is really amazing, but is it really safe to transport these cars in such a way?

I Thought this was a story on transporting cars by train and not a commentary on how much you hate Chevy Vega's.

--

Actually, because traincars are loaded from the center, the picture is correct. The three photos underneath that statement show them load the one end, turning the cars through the doors in the center, and then start to load the other end.