New Advances in the Bamboo Bicycle: Semester HexTube Bamboo + Carbon Fiber Bike

Text & photos by Lance Gordon Rake / Semester

For the last two years, I've been working with John Bielenberg and HERObike, an initiative in Greensboro, Alabama, that is creating economic opportunity in the heart of the rural South by harvesting local bamboo to manufacture bicycles.

John was the reason I came to Greensboro in the first place: He had been helping HERObike produce a bamboo bicycle, taking advantage of an incredible local resource. They started making bamboo bikes using pans and jigs from the Bamboo Bike Studio. They still offer workshops where people can come to Greensboro and build their own bamboo bike in a weekend. It's a great service, but John and I were both convinced that we could design a better bamboo bike. The resulting Semester bike is unique and represents a leap forward in bamboo and bicycle frame design.

As you can see, this is not your typical "Gilligan's Island" bamboo bike! The design instead takes inspiration from the bamboo fly rod, using hexagonal composite bamboo and carbon fiber tubes along with steel lugs and stays. The resulting bike gains lateral stiffness from the steel rear triangle, but vertical vibration dampening from the composite tubes. The resulting ride is relaxed yet responsive—perfect for the city and makes a great everyday bike.

The Materials Innovation

As I understand it, golden bamboo, the kind we are using in Greensboro, was introduced in Alabama in the late 19th century. It is used for screening purposes and sometimes you'll see it used in a garden, but I rarely see it used for its functional properties. Small canes are sometimes harvested for bean poles, and I'm sure the occasional cane fishing pole is still cut, but large stands of bamboo go largely untouched.

The hexagonal shape was inspired by my memories of bamboo fly rods. I think of these rods as having an heirloom quality: they're both absolutely beautiful and extremely functional. These rods are not to be confused with cane fishing poles. Bamboo is split, planed to precise sections, and laminated together to form a tapered, hexagonal form. Lightweight and responsive, they have been favored by fly fishermen for generations and are still preferred by many over carbon fiber alternatives. I was looking to capture the precision, strength and responsive feel of the bamboo rod in a high performance bicycle frame.

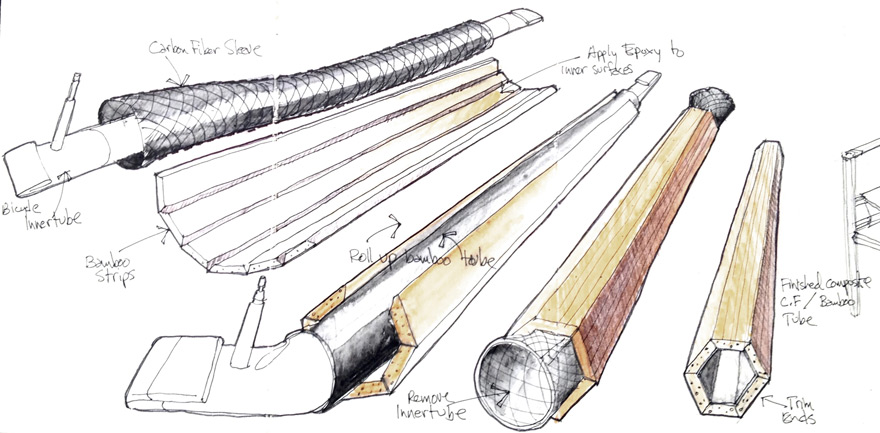

The carbon fiber part of this project came to me later. I was at the NAHBS in Sacramento in 2012 in Sacramento, where I saw a titanium frame that was lined with carbon fiber. The primary advantage, I was told, is to negate vibration by fusing two dissimilar materials. That made sense to me, but if I was going to do this, I'd have to find a simpler, cheaper way to do this (they were using an autoclave). I developed a process using a length of bicycle innertube as a bladder to expand a braided carbon fiber sleeve to the inner wall of my hextubes in epoxy resin, laminating them tightly together. It worked beautifully, making the tubes stronger and stiffer, and practically eliminating vibration.

While researching ways to weatherproof the tubes, I looked at cedar strip canoes, which are lined inside and out with woven fiberglass cloth and epoxy. When properly "wetted out," the fiberglass is perfectly transparent and extremely durable. I had arrived at a "stressed skin composite" material—many examples exist in aircraft construction—with braided carbon, bamboo and fiberglass combined to make a near-perfect structural element for bicycle construction. The continuous, parallel bamboo fibers run the length of the tube, and the fibers in the carbon fiber and FRP are laid diagonally, giving us torsional rigidity. Full carbon frames do not have the same vibration dampening afforded by bonding dissimilar materials.

The Economic Impact

I have served as an advisor for Project M [which was behind the Alabamboo project], but this project is independent of that effort. It is, however, associated with HERO, a great non-profit organization located in Greensboro that runs HERObike in order to create jobs and provide training opportunities for young people in the community. It's an amazing effort headed by Pam Dorr.

The goal of this project is to not only produce a better bamboo bicycle, but to provide jobs in an area in need. The project centers around the town of Greensboro, AL. All of the bamboo for the Semester Bicycle is grown behind the workshop, and every tube is assembled in Greensboro by people from the community.

I always thought that industrial designers create some amazingly cool products and some absolutely soul-crushing, menial jobs. I am hoping that the people building these bikes will find the work rewarding, challenging, and satisfying. Fabrication is scalable, but will always require high-skilled craftspeople with a passion for making beautiful, high-performance bicycles.

Additional details, video and more images can be seen on our Kickstarter page.

-

oFavorite This

-

Q2Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

http://4.bp.blogspot.com/-LKqtaLt91TY/T5lmGcMgCzI/AAAAAAAAARo/JIPWWMZfE80/s640/2.jpg