Looking Back to Save the Future

Designing products to take advantage of sustainable production methods can often be a better approach

Edited by Emily R Pellerin

The common narrative of industry is of a steady march of progress, improvement, and innovation since the beginning of the industrial revolution.

Innovation's superiority complex touts itself as "better," kicking "inferior" methods on the curb in its pursuits. There's a misconception embedded in the narrative, though: the fallacy ignores the fact that older manufacturing methods are often more sound in economic, ecological, industrial senses and beyond.

The Radicality of Using Craft

Newer methods of making often prioritize assembly techniques and materials that are unhealthy for the employees making the products, for the consumer, and for the planet. (Read more about the importance of these ideas, through the lens of design for disassembly, here.) It often goes overlooked that sometimes, the most environmentally sustainable design solutions can be found by looking to our past.

That's not to say it's always overlooked. Designer-activist Julia Watson has published inspiring research on how ancient and current indigenous technologies can be beacons for our path towards more sustainable farming and building practices; even way back in the 1960s, architect-historian Bernard Rudofsky similarly looked at "vernacular architecture" for answers beyond the narrow confines of the practice's conventions.

However, while research may abound on this approach of "looking back to save the future" in architecture, there has not been much attention granted to this idea in product design.

In a world increasingly detached from traditional making processes (built instead on complex digital technologies and business motivations), the types of practical solutions, simplification, and basics-forward designs that borrow from the past are, at this point, truly radical. Hands-on craft disciplines like textiles, ceramics, weaving, furniture making, upholstery, and metal smithing have ancient roots – and they offer necessary lessons for contemporary making.

Why is this so radical?

There's a fetishization in the design world of novelty and new processes. In product design, an interest in past technology calls to mind associations with Luddites or brings up arguments of elitism, in that these processes can only work with small-scale or expensive manufacturing.

These perspectives, though, harbor an embedded fallacy: contrary to what we often seem to understand, traditional and past methods are not mutually exclusive from technological advancement (an idea so counter-narrative that its radicality is self-contained). To reexamine the making methods of craft-based and indigenous cultures is to often find sophisticated, elegant and more holistic solutions that were eradicated (or at least tossed aside) in the name of progress.

To breach this fetishization of novelty represents an exciting fissure, as it allows us to expose the mutual benefit of new processes in tandem with age-old design techniques.

A return to making & craftsmanship

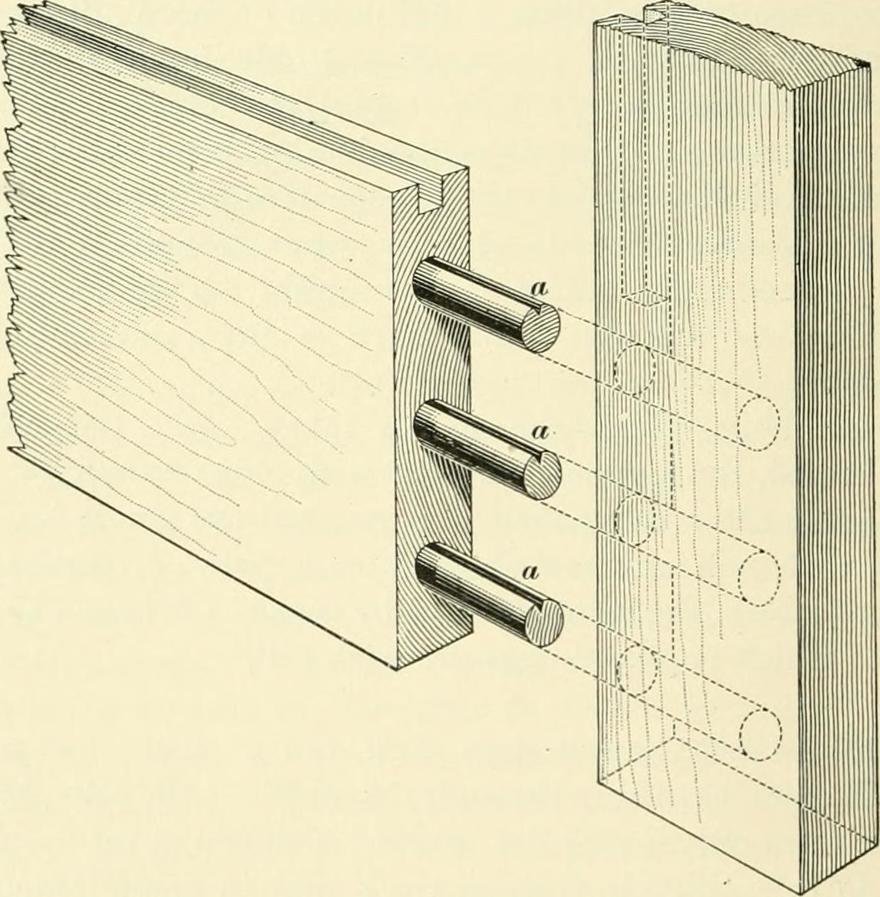

With sustainability as our vantage point, it's easy to find examples from historical furniture that demonstrate methods known to reduce our carbon footprint. Inventive wood joinery, metal hardware, and upholstery techniques point to ways that industry can revise current product designs to streamline material use, assembly methods, and packing/shipping.

A page from "A treatise on architecture and building construction" (1899), p. 507

A page from "A treatise on architecture and building construction" (1899), p. 507

These methods are the tip of the examples-iceberg in terms of representing historical precedents of contemporary sustainable design theories (think: "design for the circular economy" or "Design for Disassembly").

"I turn a lot towards traditional wood joinery that doesn't require fasteners and glue," says Jonsara Ruth, a furniture designer and the hyphenate Design Director and Co-Founder of the Healthy Materials Lab at Parsons School of Design. She cites an "obsession" with Asian joinery as an illustration of how applying traditional design to modern making is in fact the far-improved way to go. "The complex joints create such strong connections. A whole building can be built with traditional wood joinery! Instead of hand-carving the precise shapes of the joints, [we now] can use 3-axle milling machinery to make that joint, and it can last for decades and decades and be disassembled later."

As contemporary makers and educators are shifting the literacy around these techniques and design methodologies, we have started to see larger design brands follow suit. It's an exciting bellwether for the maturation of our collective material intelligence – an industry-wide arena in which we all still have ample room to grow.

As Glen Adamson lays out in his book "Fewer, Better Things," material intelligence is both an intuitive and learned understanding of the nuances, properties and behavior of materials.

As Glen Adamson lays out in his book "Fewer, Better Things," material intelligence is both an intuitive and learned understanding of the nuances, properties and behavior of materials.

A more "materially intelligent" design

Contemporary furniture factories across the U.S. – contracted by larger design, furniture or home goods brands – commonly use spray adhesive to attach cushioning to frames. A neglected side effect is the adhesive's contribution to unhealthy air for the employees making the furniture, as well as off-gassing in our homes. This also prevents the furniture components from being easily refurbished or later reclaimed as technical or biological nutrients.

This is not to the fault of any one person – manufacturers, like we all do, make choices based on long-standing habits, and often don't have the luxury of time to reconsider the way they make things. Updating adaptations of the traditional techniques is an opportunity to reconsider how and why we design products the way we do.

When I was contracted as a designer and consultant for the furniture company Sabai Design, for example, we replaced their glue with traditional upholstery techniques that used mechanical fasteners and natural materials. This was one of many decisions I helped them with in terms of redesigning their existing product line to reach their sustainability goals. Lest you scoff at how this will increase the cost of the furniture, the overall costs of goods sold was in fact reduced by about 7%.

A final example

Jonsara Ruth shares a case study from her work with the furniture company Q Collection. After their original factory-collaborator sadly shuttered its doors, the team began working with Amish factories in the Midwest. "I was blown away because they had passed down, for generations, these ways of making things that are very sustainable and that don't use adhesives."

She describes a vivid scene in which the workshops fueled furnaces with lumber scraps, creating steam that they would then use to steam-bend wood. "The curves of the wood meant that they could eliminate adhesives and hardware while still creating complex forms. A traditional factory would use screws and glue and plug the holes [but] the Amish factory would bend the wood to create an arch, and peg it."

For the furniture company, this return to traditional methods was profound. For Ruth, it was also philosophical. "I get passionate about the craftsmanship angle because there's a lot that can be done by thinking about how something is made. I didn't invent a new process," she acknowledges. "I just designed the furniture in a way that it could be made with traditional methods." She prioritized the challenge of reducing materials, and took a brave approach to eliminating hardware. "It's about smart manufacturing," she says, and, equally as importantly, "it's a mindset."

Where have you seen a revisiting of craft methods in the design industry? Have you practiced it in your own work? What historical methods or approaches should we be integrating into contemporary design? Share your thoughts, suggestions, and stories in the comment section below.

-

o7Favorite This

-

Q5Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

I chuckle when "looking back" is critiqued as inaccessible - sure, especially in the decorative arts, we cannot make those products affordable when its creators want to earn a decent living by today's standards, but so often their labor-intensity was precisely the point. Common craft skills are things that almost anyone can make, with minimal capital investment. It's mostly not scalable in the sense that "I" can't make it at scale to sell to everyone else. The Shakers, members of the Arts & Crafts movement were still looking for ways to conspicuously feature the human labor input. Joiners featured "marks of good craftsmanship" that often featured guild secrets. "Primitive" techniques are, by definition, accessible. Ironically, I think Nakashima is an excellent example of navigating the economies of making simple, beautiful, durable furniture: they use machine turned spindles, and departing from the aesthetic of large slabs, they generally use seats made from a panel made from several boards. So much craft had to change in response to economics of machinery: ex. building with sawn lumber instead of riven lumber. Today's technology should be able to serve the opposite goal: identify and produce materials suitable to intermediate-skill (as opposed to de-skilled or guild/artisan) manufacturing techniques. A designer closer to the build-process, rooted in place, is most certainly a scalable model (just not in the sense that any one business entity could capture most of the value). I look to body shops as an analogy: you want your bodyman to be local not because you expect to visit them frequently, but they know local styles, practical considerations with climate and road conditions. If you mention a car in the area you'd like to emulate, not only have they probably seen it, but they've already spent some time thinking about it. A builder-designer in a city may well consider the flooring, the size of doorways, height of ceilings, etc..

Hard to believe there is much of a case for disassembly/ reuse. What you start with is so unpredictable, it's a small scale craft operation. Thank God, furniture at least is made on such a low volume basis that you can't get a uniform product out of recycling it. In most cases, the resulting boards are so small there is not much future for them. The exceptions, panels from case goods, sideboards from bed frames, are then limited in volume while varied in species, cut, material, color.

Just a thought... I wonder how sustainability certifications (in timber or plastics e.g.) could work in tandem with craft-based methodologies somehow to help guide the whole economy of making toward circularity. If all materials were used with these disassemble-able, bio-reusable making methods, that could be really dramatic -- or if there were sort of reciprocal requirements for certification, e.g. where not only is the MATERIAL certified, but the usage also has to be too. I don't know... crossed my mind as I read these beautiful anecdotes from Jonsara!