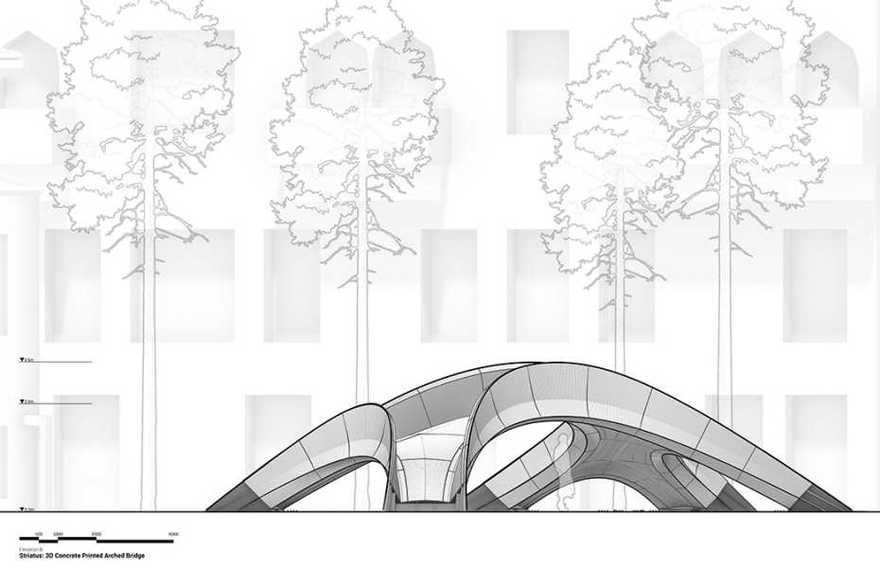

This Self-Supporting 3D-Printed Concrete Bridge Uses Less Material

By Zaha Hadid Architects and ETH Zurich

Swiss public research university ETH Zürich has teamed up with Zaha Hadid Architects to create a new type of bridge that uses less material and enables new types of forms.

By 3D printing concrete at specific angles, the collaborative team was able to produce blocks with layers "orthogonal to the flow of compressive forces," allowing them to design differently-shaped blocks for different portions of the bridge.

On-site these blocks are fitted together in the manner of traditional stone arches—i.e. the structure is self-supporting—but the arrangement allows for wildly organic shapes that no traditional stonemason could ever hope to work out on paper:

The blocks stick together through gravity, meaning no mortar is required. No steel reinforcements are necessary, either. And if needed, the entire bridge can simply be disassembled and reassembled elsewhere.

"This precise method of 3D concrete printing," says ETH professor Philippe Block, "allows us to combine the principles of traditional vaulted construction with digital concrete fabrication to use material only where it is structurally necessary without producing waste."

However, as with 3D printing certain forms in plastic, temporary support is needed. In this case, a rather comprehensive OSB scaffolding has been erected, with the parts having undoubtedly been cut with a CNC mill. This should offset the resource savings somewhat, but we assume that on-balance, they're still in the black.

The video has additional details:

Enter a caption (optional)

-

o1Favorite This

-

Q1Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

this looks great. i hope they take this really far. they could even incorporate other elements, like solar powered lighting for underneath, troughs for plants or vines to grow on it. seating, railing, handicap access, etc., etc.