MakerBot Releases 3D Printing Trends Report

The stats say you're probably a North American male engineer for whom accuracy isn't super important

Today MakerBot has released their new 3D Printing Trends Report, which lists statistics from "over 1,200 responses from professionals across multiple industries, including Aerospace, Industrial Goods, Military & Defense, Medical, and Automotive." We could cut-and-paste the whole thing here and you'd find it interesting, but then we'd be stealing clicks, so I'll just mention some of the stats that jumped out at me:

Fused deposition modeling dominates. 77% of respondents use FDM, whereas 27% use SLA.

Half of 3D printing users worldwide are in North America. I figured Europe's much lower numbers were the result of the population differential, but that does not explain Asia's relatively small numbers.

Overlapping with people who find Lamborghinis cool, 3D printing users are overwhelmingly male.

Of any given 3D printer user, it's almost twice as likely that they're an engineer as opposed to a designer.

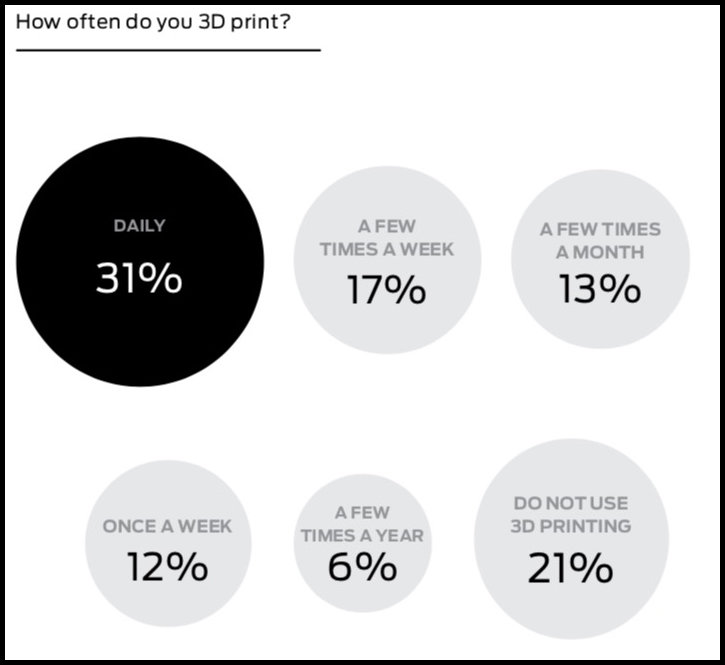

The largest percentage of 3D printer users print with it every single day.

Unsurprisingly, plastic is the go-to 3D printing material.

I found this surprising: Of all the criteria for selecting a 3D printer, "Print accuracy/high resolution" garnered the highest share of votes--yet only 60% of respondents rated the quality as "Very important.

Based on the stat above, high precision is apparently not as crucial as I'd have guessed it would be. Backing that up is the stat below, showing that reliability is more important to end users than dimensional accuracy.

You can download the full report, for free, here.

-

oFavorite This

-

Q3Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

Yup :) I agree with both replies up here :)

I think that with FDM (makerbots bread and butter) reliability of the machine is the most important thing. I remember spending hours replacing parts, calibrating and cleaning the machine just to keep it going. I would simply print in the fastest but still reliable settings, and test the prototype to see if it would work. The aesthetics of the print wouldn't matter.

I now use SLS on a form3 and I see that I now also start to look at the finish of the product, but I still print with the fastests settings . :)

Not to deter from what is obviously a lot of work and still very interesting, I would take this report with a pinch of salt. The main 'cluster' of participants would be somehow affiliated to Makerbot, a North american, 3d printing manufacturer.

My guess is that printing (FDM) at a higher resolution to get higher accuracy/"Takes a lot longer", is the reason that others are not placing such a great value on it. They simply don't want to wait for the part twice a long to only get a fractional increase in accuracy.....Just my guess of course.