- Student

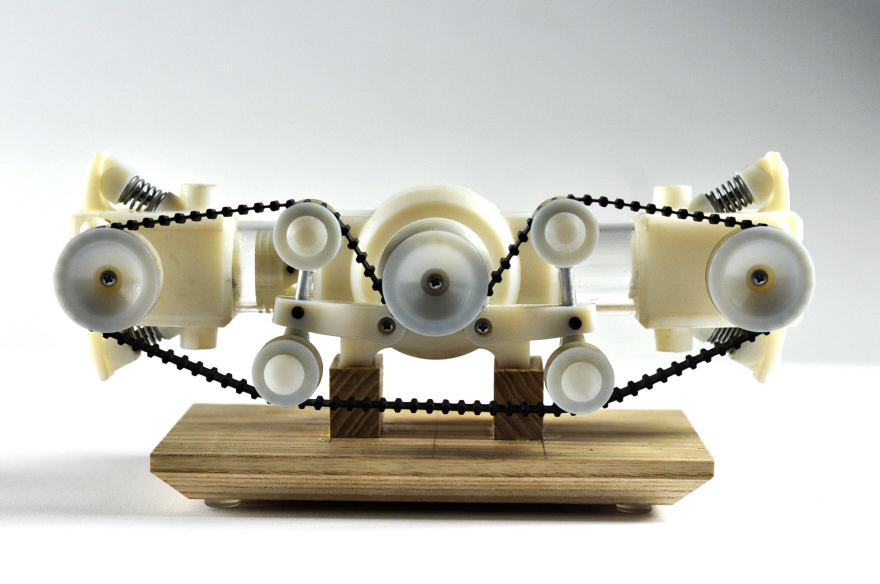

3D Printed Engine

This 3D printed model is based on a flat two-cylinder internal combustion engine. Engines using this geometry are commonly found in motorcycles and small aircraft. The design is intended for the specific process and materials used in 3D printing and the model is not based on any specific engine design.

Design Team

Elliot Ouchterlony

This engine model was designed in Solidworks to be printed on an Objet 3D printer.

Most of the significant design decisions went into the valve configuration, which extends from the end of the clear cylinders. Building components that were small enough to fit into the valve housings, while being strong enough to hold up to the forces applied on them, took a great deal of iteration. Parts of the valve, including the springs, some metal components, and the clear cylinders, were fabricated to fit together with the printed components.

A single timing belt synchronizes the valves and crankshaft. Four separate pulleys tension the belt. The timing of the belt to the valves is one to one; this makes the cycle appropriate for running on compressed air as opposed to internal combustion.

The crankshaft drives a built in epicyclic reduction gear system. The gearbox is built directly into the engine block. Altogether the engine is comprised of forty-four printed parts and fifteen off the shelf or fabricated parts, not including the wooden stand and fasteners.

Check out a video of the engine in action here.

-

oFavorite This

-

QComment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.