A Chemical-Free Way to Preserve, and Beautify, Wood: Set It on Fire

The Japanese "shou sugi ban" method gives wood a protective finish and can yield stunning aesthetic effects

In the Manhattan blocks surrounding us are a Maya-Lin-designed museum with exterior wood cladding, a French restaurant with exterior wooden planters, and a bar with an outdoor wooden bench. These wooden surfaces looked great when they were first installed--then went to hell after just one or two NYC winters. If wood is going to sit outside, it needs to be treated in order to weather the elements.

That treatment can consist of slathering it in exterior-grade paint or nasty chemicals, and is far from a permanent solution; long-term homeowners among you know you must have your house repainted every ten years or so, and there's often sticker shock at how expensive this can be. A better way to go might be to pre-treat the wood not with chemicals, but with fire.

A centuries-old wood-treating method from Japan called shou sugi ban ("burnt cedar board") consists of charring the surface, then brushing off the burnt bits. Here's what it looks like, and it gets a tung oil treatment at the end:

Pre-burning the surface like this actually makes the wood more resistant to fire, a serious concern in 1700s Japan (when the technique was commonly used), as all houses then were made out of wood. But the developers of this technique also discovered that it made the wood more resistant to both rot and pests. More recently it's been discovered that the charred wood is also UV-resistant.

As a result, a shou sugi ban finish can reportedly last for some 80 to 100 years, virtually maintenance-free. (This is not only easier on the wallet, but allows you to participate in the global trend of letting future generations worry about fixing up your stuff. Score!)

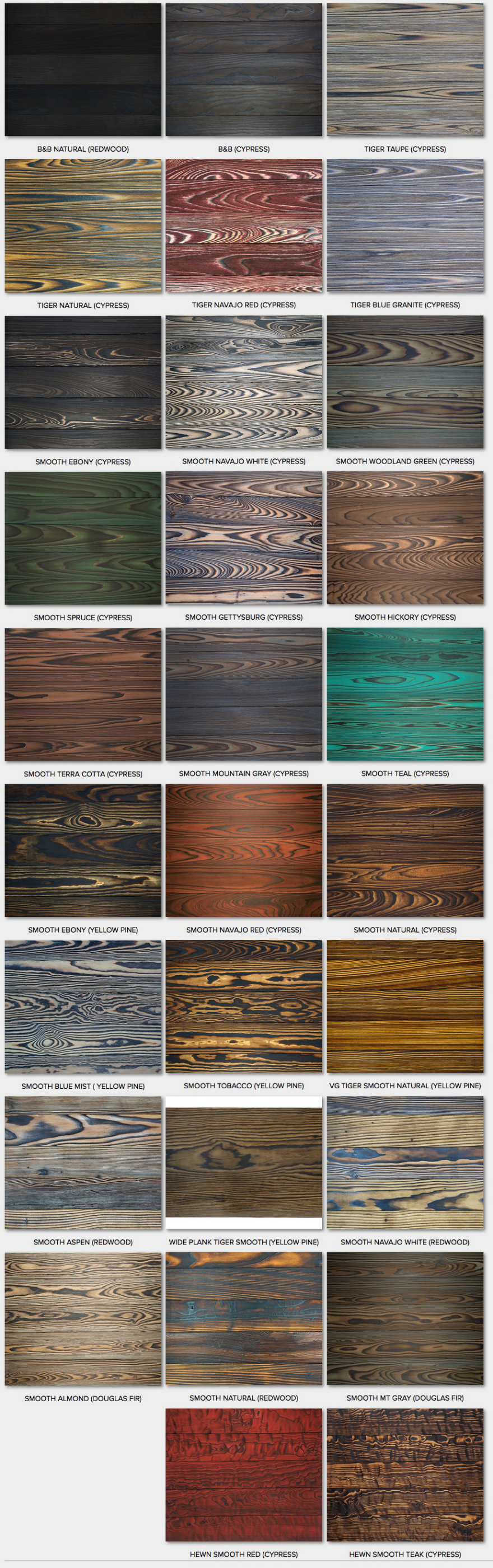

Some American firms have adopted the technique, having learned of its preserving effects, and put their own spin on it. Texas-based Delta Millworks, for instance, has applied it to far more breeds than the Japanese Cedar it was originally designed for, offering a stunning range of aesthetics:

Image/work by Delta Millworks

Image/work by Delta Millworks Here's a video of them applying a "gator" finish where the charred surface is not removed, providing an interesting look:

Another firm specializing in shou sugi ban is Charred Wood LLC, based up in the Pacific Northwest. On their website they've got this photo, caption theirs:

"Japanese Architect Terunobu Fujimori Creating Shou Sugi Ban the Traditional Way in Japan."

"Japanese Architect Terunobu Fujimori Creating Shou Sugi Ban the Traditional Way in Japan." Seeing that makes me wonder: Given that the technique predates industrialization, what do you reckon they used to scrape the surface, in the days before wire brushes? Somehow I don't see hoghair brushes cutting it, nor would traditional Japanese blades be appropriate for the job. Any guesses?

-

o1Favorite This

-

Q4Comment

K

{Welcome

Create a Core77 Account

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

K

Reset Password

Please enter your email and we will send an email to reset your password.

Comments

I have an observation on how well the "gator" finish holds up.

v=JTWKV6bynuA

v=u00ZRvQv7vY

I am interested in using this method for preserving large tree slices. I will treat the slices first with a wood stabilizer to prevent cracking and splitting. I have only seen this method used on planks and sheeting. Do you think this method would work on tree slices? I am concerned that the grain runs in the opposite direction. My slices are 2-3 feet in diameter and 3-4 inches thick.

Very interesting! Have question though. During installation do you torch the end cuts and any other fabrication required for actual application of the siding?

The Japanese have traditional stiff bristle cleaning brushes made of natural fibers that would probably do the trick for the brushing stage. See this: